ARC WELDING WITH COATED ELECTRODES (M.M.A. Manual Metal Arc)

A. INTRODUCTION

Arc welding with coated electrodes is a manual process where the heat source consists of the electric arc.

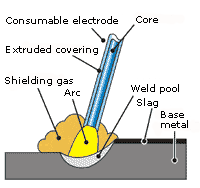

When the arc strikes between the coated electrode ( by means of an electrode holder clamp) and the piece to be welded (base material), it generates heat which causes rapid melting of both the base material and the electrode (weld material).

B. THE WELDING CIRCUIT

1. power source

2. electrode holder clamp

3. coated electrode

4. earth clamp

5. clamp and earth cables

1. POWER SOURCE

The purpose of the power source is to feed the electric arc, which is present between the base material and the electrode, through the output of a current sufficient in quantity to keep the arc struck.

Electrode welding is based on the constant current principle i.e. the current delivered by the power source should not vary when the operator moves the electrode towards the piece. The main construction property of the source is therefore to keep the current unchanged in the presence of variations in arc length as the electrode moves closer to or away from the piece: the more constant the current, the more stable results the arc and the simpler the operator’s work.

Inside the power source, there is usually a welding current adjustment device, of a mechanical (magneticshunt or saturable reactance) or electronic type (SCR systems or inverter systems). This distinction can be used to classify electrode welding machines into three families, depending on their construction technology: electromechanical welding machines, electronic welding machines (SCR), inverter welding machines.The polarity of the power source output current distinguishes two further categories:

a) Alternating current (AC) power source

The power source output current takes the form of a sine wave, which changes its polarity at regular intervals, with a frequency of 50 or 60 cycles per second (Hertz). It is obtained using a transformer, which converts the mains current into a suitable current for welding. This is for electromechanical welding machines.

b) Direct current (DC) power source

The power source output current has a continuous wave form, which is obtained by means of a device, the rectifier, which is situated at the base of the transformer and can convert from alternating to direct current. This output is typical of electronic SCR and inverter power sources.If the welding circuit has a direct current (DC) power source, it can be further classified according to the method of connecting the power source poles to the material to be welded

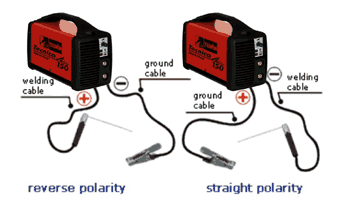

i) Straight polarity connection

Straight polarity connection occurs when the clamp cable (with the electrode holder clamp) is connected to the negative pole (-) of the power source and the earth cable (with the earth clamp) to the positive pole (+) of the power source. The electric arc concentrates the heat produced on the piece and causes its melting. In this way, as the core of the electrode melts, it is deposited and penetrates into the welding joint.

ii) Reverse polarity connection

Reverse polarity connection occurs when the clamp cable (with the electrode holder clamp) is connected to the positive pole (+) of the power source and the earth cable (with the earth clamp) to the negative pole (-) of the power source. The heat of the electric arc is mostly concentrated at the tip of the electrode.Each type of electrode requires a specific current type (AC or DC) and, in the case of DC current, a specific polarity: the choice of the electrode therefore depends on the type of power source used. Incorrect use will cause arc stability problems and hence also welding quality problems.

2. ELECTRODE HOLDER CLAMP

The primary function of the electrode holder clamp is to support the electrode, guaranteeing a good electrical contact for current passage; it should also guarantee sufficient electrical insulation for the welding operator.

3. COATED ELECTRODE

The coated electrode consists of a core and a coating which have different but complementary functions: the core acts mainly as a conductor for the arc power supply and as supplier of the material that fills the joint; the coating, on the other hand, has the main function to protect the weld pool and stabilise the arc.

4. 5. EARTH CLAMP AND CABLES

The earth clamp is a tool that, via the earth cable, ensures the electrical circuit to be closed between the welding power source and the piece to be welded. The clamp and earth cables, connected to the electrode holder clamp and earth clamp respectively, permit an electrical connection between the power source and the base material to be welded. The choice of cable section and length should be based on the maximum welding current in amps.

C. THE ARC FORCE, HOT START AND ANTI STICK DEVICES

Welding power sources may contain special devices whose functions is to facilitate their use. These devices are described as follows: arc force, hot start and anti-stick devices.

The arc force device eases the transfer of drops of melted material from the electrode to the base material, preventing the arc from extinguishing when the drops cause contact (i.e. a short circuit) between the electrode and the weld pool.

The hot start device facilitates the striking of the electric arc, by supplying an overcurrent every time welding restarts.

The anti-stick device automatically switches off the power source if the electrode sticks to the base material, thus allowing it to be removed manually without ruining the electrode holder clamp.

D. COATED ELECTRODES

1. 1 Features -The coated electrode consists of a core and a coating:

-The coated electrode consists of a core and a coating:

the core consists of a metal conductor rod whose sole purpose is to supply welding material to the piece.

The material used depends on the base material: for carbon steels, for which electrode welding is most widespread, the core is in mild steel. During welding the core melts slightly before the coating does.

-the coating is the most important part of the electrode and has many functions. It primarily serves to protect the weld from air contamination, and it achieves this in different ways.

By volatilizing, and then modifying the atmosphere surrounding the weld pool; by delay melting and consequently by protecting the core with the naturally formed crater; and by liquefying and floating on top of the pool. It also contains material capable of purifying the base material and elements that could contribute to the creation of alloys in the melt. The choice of coating is therefore very important and depends on the characteristics to be given to the weld. The coating can also contain weld material as a powder, to increase the quantity of deposited material and hence the welding rate. In this case we refer to high performance electrodes.

1. 2 Electrode categories

Various types of coated electrodes are available on the market, and their chemical composition has a strong influence on electric arc stability, penetration depth, material deposit, pool purity i.e. on their fields of application.

According to the coating type, the main types of electrodes are:

* electrodes with acid coating

The coatings of these electrodes consist of iron oxides, iron alloys of manganese and silicon. They ensure good arc stability making them suitable for both alternating current (AC) and direct current (DC). They have a very fluid weld pool which makes welding in position impossible; moreover, they do not have a great ability to clean the base material and this could cause cracks.

They will not withstand high drying temperatures, with the consequent risk of residual humidity and therefore hydrogen inclusions in the weld.

* electrodes with rutile coatings

The coating of this electrode consists essentially of a mineral called rutile. This consists of 95% titanium dioxide, a very stable compound that ensures optimum arc stability and high weld pool fluidity, which has a noticeable effect on the appearance of the weld. The function of the rutile coating is, however, to ensure a soft melt that is easy to realise, and facilitates the formation of an abundant, viscous slag that gives good flowability into the weld, especially in a horizontal position. In this case the seam has a pleasing, regular appearance. Unfortunately, like the above, these coatings are not very effective cleaners either, so they are recommended when the base material does not contain many impurities; moreover, they cannot be dried perfectly so a large quantity of hydrogen is generated in the weld.

In some applications rutile is combined with another component that is typical of other coatings, such as cellulose (rutilcellulose electrodes) or fluorite (rutilbasic electrodes). Their usual purpose is to obtain an electrode with a stable arc that gives a higher performance weld.

Arc stability is a property that enables this electrode to be used with both alternating current (AC) and direct current (DC) in straight polarity. It is mostly used on low thicknesses.

* electrodes with cellulose coatings

The coating of these electrodes consists mainly of cellulose integrated with iron alloys (magnesium and silicon). The coating gasifies almost completely, thus allowing welding in a descending vertical position, which cannot be achieved with other types of electrode; the high gasification level of the cellulose reduces the quantity of slag present in the weld. The generation of a large quantity of hydrogen (derived from the particular chemical composition of the coating) ensures a “hot” weld pool, with the melt of a considerable quantity of base material; it is thus possible to obtain high penetration welds with little slag in the pool.

The mechanical properties of the weld are optimal; the appearance is rather poor since the almost complete absence of liquid protection given by the coating does not allow the pool to be shaped during solidification.

Given the poor arc stability, the welding current is usually direct (DC) with reverse polarity.

* electrodes with basic coating

The coating of basic electrodes consists of iron oxides, iron alloys and primarily calcium and magnesium carbonates which, with the addition of calcium fluoride, obtain fluorite which is a mineral used to facilitate melting. They have a high base material purification capacity, so that high quality welds are obtained with considerable mechanical strength. These electrodes also withstand high drying temperatures so that they do not contaminate the pool with hydrogen. Fluorite makes the arc very unstable: the pool is less fluid, there are frequent short circuits due to the transfer of large drops of weld material; the arc should be kept very short due to the low volatility of the coating; all these properties need the presence of an experienced welder. The welds have a hard slag which is difficult to remove, but must be completely removed for repeated passes. These electrodes are suitable for horizontal, vertical and overhead welding.

As regards the current to be employed, the use of direct current (DC) power sources with straight polarity is recommended. Basic electrodes are distinguished by the very high quantity of material deposited and are well adapted to welding high thickness joints. They are very hygroscopic and should be kept in a dry place in a hermetically closed container; if this is impossible, we recommend drying the electrode again before using it.

1. 3 Properties of the various types of electrodes

| TIPO | VANTAGGI | SVANTAGGI | APPLICAZIONI |

|---|---|---|---|

| acid | low coststable arcAC and DC currenteasily removable slaghigh deoxidationeasy storage | fluid poolpoor cleaning effecthigh hydrogen generationslag cannot be remelted | horizontal weldinglow carbon steels with few impuritieslow cost welds with passable mechanical properties (good strength but risk of cracks) |

| rutile | low coststable arceasy strikeAC and DC currentbetter appearance of seameasy storage | fluid poolpoor cleaning effecthigh hydrogen generation | horizontal weldingvertical and fillet welding for low thicknesslow carbon steels with few impuritieswelds with good appearance but only passable mechanical properties (good strength but risk of cracks) |

| cellulose | high penetrationgood workabilityreduced slag | DC power sources with high no-load voltage are necessaryirregular seamhigh hydrogen generation | welding in all positions, including descending verticalpipes or whenever a return from the back is impossiblewelds where electrode access is criticallow carbon steels with few impurities |

| basic | excellent material purifiervery low hydrogen generationcold pool | low stability arcslag cannot be remelted and difficult to removeshort arc and low workabilitydifficult strikeDC power sourcedifficult storage | welding in all positions, even at high thicknesshigh deposit rateshigh mechanical quality welds, even with materials containing impurities |

1.4 Choice of current for the various types of electrode

| Electrode diameter (mm) | 1,60 | 2,00 | 2,50 | 3,25 | 4,00 | 5,00 | 6,00 |

|---|---|---|---|---|---|---|---|

| Acid electrode | – | – | – | 100-150 | 120-190 | 170-270 | 240-380 |

| Rutile electrode | 30-55 | 40-70 | 50-100 | 80-130 | 120-170 | 150-250 | 220-370 |

| Cellulose electrode | 20-45 | 30-60 | 40-80 | 70-120 | 100-150 | 140-230 | 200-300 |

| Basic electrode | 50-75 | 60-100 | 70-120 | 110-150 | 140-200 | 190-260 | 250-320 |

2. Classification of the electrodes

According to the standard EN 499, coated electrodes are classified into groups depending on the type of coating and their most important properties.

a) According to current standards, each electrode can be completely defined by an identification given on the package cover, as in the example below:

| E | 44 | T | 3 | C | 1 | 9 | R09 | KV20 |

The meaning of which is given here below:

* E = electrode

* 44 = tensile strength, which can be:

00 = no guaranteed value;

44 = minimum guaranteed value 44 Joule

* T = Type of application which can be:

S = for thin sheets (below 4 mm.);

L = for medium and thick sheets;

T = for piping.

* 3 = quality class, which can be from 1 to 4, increasing as particular mechanical tests are passed.

* C = Type of coating, which can be:

R = rutile RC = rutile cellulose

B = basic RB = rutile-basic

C = cellulose V = special (to be specified on the package)

* 1 = welding positions, which can be:

1 = all

2 = all, excluding descending vertical

3 = only horizontal and frontal-horizontal (normal angle)

4 = only horizontal and positioned angle.

* 9 = current to be used, which can be:

* R09 = minimum guaranteed efficiency, expressed in tenths;

* KV20 = extra symbol for low temperature impact resistance properties; in the example the electrode has an impact resistance value down to -20 °C.

b) Given the increasing use of the AWS (AMERICAN WELDING SOCIETY) and ASTM (AMERICAN SOCIETY FOR TESTING AND MATERIALS) classification among Italian users, each electrode is described by the manufacturer’s logo as well as by a symbol as in the following example:

| E | 60 | 1 | 1 |

The meaning of which is reported here below:

E = electrode

60 = minimum tensile strength, expressed in pounds per square inch

1 = welding positions which can be:

1 = all

2 = horizontal and positioned angle

1 = welding current, which can be:

0 = direct with electrode negative polarity, for cellulose electrodes;

1 = alternating and direct (positive pole)

2 = alternating and direct (negative pole)

3 = alternating and direct for rutile electrodes

4 = alternating and direct for high performance rutile electrodes

5 = direct with electrode negative polarity for basic electrodes

6 = alternating and direct for basic electrodes

7 = alternating and direct (any pol.or neg.pole only) for high performance iron oxide

8 = alternating and direct (positive pole) for high performance basic electrodes.

E. MATERIALS WELDED BY MMA

When the steel composition is easily identifiable, rutile electrodes can be used as they are easier to strike and to weld and give a good-looking seam.

In practice, welding of medium, high carbon steels (>0.25%) can cause the formation of structural defects; application of the electrode procedure is recommended mainly for welding medium to thick joins using basic electrodes: in these cases a high quality weld is obtained with good breakage resistance.

Steel pipe welding is carried out using cellulose electrodes, where high penetration and good electrode workability are required. Bevelling is always recommended, with a bevel angle that is sufficient to allow almost complete electrode insertion into the welding gap.

For special materials such as stainless steel, aluminium and its alloys, cast iron, specific electrodes for the particular material are used.

Stainless steels are welded with direct current (DC) with reverse polarity; special electrodes are used and are differentiated by the metallurgical composition of the material to be welded (presence of chrome (Cr) and of Nickel (Ni) in variable proportions).

Aluminium and light alloys are welded with direct current (DC) with reverse polarity. The machine should be equipped with rather a high strike dynamic to guarantee electrode strike.

Also in this case special electrodes are used and are differentiated by the metallurgical composition of the material to be welded (presence of Magnesium (Mg) and of Silicon (Si) in variable proportions).

Cast iron is welded with direct current (DC) with reverse polarity; the majority of cast iron structures and machine members are obtained by casting, so that welding is used to correct possible casting defects or for repairs. Special electrodes are used and the base material should be heated sufficiently before use.