ARC WELDING WITH CONTINUOUS WIRE ELECTRODE WITH GAS SHIELD (G.M.A.W.) OR WITHOUT GAS SHIELD (FLUX or SELF-SHIELDED WIRE).

A. INTRODUCTION

Continuous wire welding in a shielded atmosphere is often identified by the abbreviations M.I.G. (Metal Inert Gas) and M.A.G. (Metal Active Gas) or G.M.A.W. (Gas Metal Arc Welding). Continuous wire welding is a process in which the heat required to carry out the weld is supplied by an electric arc that is maintained between the piece to be welded and the wire electrode. The welding zone is constantly fed with the welding material (the wire electrode) by means of a special torch, which also supplies the flow of gas (or gas mixture) whose purpose is to shield the wire electrode, the weld pool, the arc and the area surrounding the base material from atmospheric contamination.The presence in the welding circuit of the gas cylinder (inert or active gas, or a mixture of the two) together with the use of solid wire electrodes, identifies the gas shield welding process (M.I.G. or M.A.G.).

Continuous wire welding in a shielded atmosphere is often identified by the abbreviations M.I.G. (Metal Inert Gas) and M.A.G. (Metal Active Gas) or G.M.A.W. (Gas Metal Arc Welding). Continuous wire welding is a process in which the heat required to carry out the weld is supplied by an electric arc that is maintained between the piece to be welded and the wire electrode. The welding zone is constantly fed with the welding material (the wire electrode) by means of a special torch, which also supplies the flow of gas (or gas mixture) whose purpose is to shield the wire electrode, the weld pool, the arc and the area surrounding the base material from atmospheric contamination.The presence in the welding circuit of the gas cylinder (inert or active gas, or a mixture of the two) together with the use of solid wire electrodes, identifies the gas shield welding process (M.I.G. or M.A.G.).

The absence of the gas cylinder from the welding circuit, together with the use of tubular wire electrodes, identifies the welding process without gas shield (SELF SHIELDED WIRE, NO GAS or FLUX); in this case the gas shield is obtained by the action of the flux core contained in the wire.

B. THE WELDING CIRCUIT

The welding circuit consists essentially of the following elements:

1. Power source

2. Torch with cable bundle

3. Wirefeeder

4. Water cooling unit

5. Gas cylinder with regulation system

6. Clamp with earth cable

1. Power source

The purpose of the power source is to feed the welding zone with the welding material, by means of a special torch, and to maintain the electric arc that is struck between the piece to be welded and the consumable wire electrode.

Unlike M.M.A. and T.I.G power sources, where there is only one regulating parameter (welding current), on M.I.G.-M.A.G. power sources there are two regulating devices, one which regulates electric arc intensity (welding voltage), and another which regulates the rate of welding wire feed (welding current).

Power sources can be divided into two categories:

a) direct current (DC) power sources

direct current power sources are the commonest power sources and are characterised by their high stability; this is because they are based on the fact that an electric arc will tend to stabilise naturally if it is powered at constant voltage and generated on a wire fed at a constant rate. Given the flexibility of the process, there is some flexibility in the choice of voltage and wire feed rate parameters. In this way it is possible to obtain drop transfer, from the welding material to the material to be welded, using either the “short arc” immersion procedure or the “spray arc” procedure.

b) pulsed current power sources

in this case it is not the voltage size that is regulated in the power source, but the current, which is not held constant but modulated with a train of impulses (hence the name “pulsed”). The purpose of the impulses is to force the drop to detach itself from the welding material; in this case the arc is not stabilised naturally, so that the impulses and wire feed rate must be perfectly synchronised to achieve an acceptable weld.

Both the in first and second case, at least two knobs are used for regulation; recent research in the industry has led to the development and marketing of “synergetic” type welding machines in which the operator uses only one control knob.

The manufacturer memorises the optimal welding parameters in the power source and these can be recalled and/or corrected by the operator, depending on the particular job requirements.

The different polarities when connecting the poles of the power source to the material to be welded identify two operating modes:

i) direct current with straight polarity connection

With electrode negative connection, the torch is connected to the negative pole and the material to be welded to the positive pole of the power source; this type of connection is only used in welding with tubular wire (FLUX).

ii) direct current with reverse polarity connection

When welding with this operating mode, the torch is connected to the positive pole and the piece to be welded to the negative pole of the power source; this is the most frequently used type of connection.

2. Torch with cable bundle

The torch, which is used to transfer the welding metal to the welding zone, has an externally insulated body and allows the passage of the wire electrode, the gas and the welding current.

Its handgrip contains a control button for switching on the current, gas output and wire electrode feed.

The cable bundle consists of a current conductor, control cables, the gas pipe, cooling water circulation pipes (if present) as well as the wire-guide sheath.There is a variety of different types of welding torches and pistols available on the market.

Water-cooled torches are used when the current intensity used is such that it generates a considerable amount of heat energy; they are used for working currents of over 300 A or for pulsed currents.

Self-cooled torches are cooled by the gas shield and are used when the working current is below 300 A; these are very commonly used.

Swan neck torches are also cooled by the gas shield and are used for low intensity current applications (immersion transfer – short arc).

3. Wirefeeder

The wirefeeder device is powered by a motor whose job is to push the wire electrode, initially wound round a reel, towards the torch and hence to the welding zone. The choice of wire feed rate value is made by adjusting the motor regulator; a given wire feed rate implies a certain melting rate and hence a defined value for the welding current. A distinguishing property of a wire puller is the number of wire-feeder rollers; devices with 4 rollers feed the wire more uniformly with respect to those with 2 rollers.

The wirefeeder device is powered by a motor whose job is to push the wire electrode, initially wound round a reel, towards the torch and hence to the welding zone. The choice of wire feed rate value is made by adjusting the motor regulator; a given wire feed rate implies a certain melting rate and hence a defined value for the welding current. A distinguishing property of a wire puller is the number of wire-feeder rollers; devices with 4 rollers feed the wire more uniformly with respect to those with 2 rollers.

4. Water cooling system

The water cooling unit is a device used to cool the torch, if it is water-cooled, should the high welding currents used cause excessive overheating. A pump ensures continuous circulation of water in the torch and, by means of a cooling system, controls overheating.

The water cooling unit is a device used to cool the torch, if it is water-cooled, should the high welding currents used cause excessive overheating. A pump ensures continuous circulation of water in the torch and, by means of a cooling system, controls overheating.

5. Gas cylinder with regulation system

The cylinder contains the shield gas/gases such as argon, helium, carbon dioxide or mixture of them, and is fitted with a pressure gauge with related pressure reducer, which is used to indicate the quantity of gas in the cylinder. It is also fitted with a solenoid valve, which are controlled by a button on the torch, to open and close the gas flow as welding is started or ended.

6. Clamp with earth cable

The clamp with earth cable is used to make the electrical connection between the power source and the base material to be welded. The section and length of the cable are determined by the maximum current from the power source.

The clamp with earth cable is used to make the electrical connection between the power source and the base material to be welded. The section and length of the cable are determined by the maximum current from the power source.

C. THE SHIELD GASES

The shield gases used in M.I.G.-M.A.G. welding procedures can be divided into two basic categories: inert and active. Argon, helium and argon-helium mixtures belong to the first type, while carbon dioxide and argon/oxygen or argon/carbon dioxide mixtures are considered active gases.

Argon (Ar) is an inert gas, produced by fractional distillation of the atmosphere. The gas is extracted from the air and may, therefore, contain traces of impurities such as oxygen, nitrogen or water vapour, but it is nevertheless considered suitable for most welding applications.

The use of this gas in M.A.G. applications gives good arc stability and an easy strike. Moreover, given its low thermal conductivity, the central part of the arc column remains at a high temperature giving more fluidity to the drops of material passing through the arc zone.

Helium (He) is an inert, rather rare gas that is scarcely present in the atmosphere and is extracted from underground: it is therefore much more costly than argon.

Compared to argon, helium has a less stable arc but greater penetration; it is mostly used for thick welds and for materials with high thermal conductivity, such as, for example, copper and aluminium.

Since helium, unlike argon, is lighter than air and hence more volatile, a greater quantity of gas is needed to ensure a sufficient shield for the welding zone.

Carbon dioxide (CO2) is an active gas, present in the air and underground. The commonest problem caused by this type of shield is that it can cause the formation of excessive spray and establish an unstable arc; if the arc is kept rather short and of constant length, however, it is possible to keep it under control. With a CO2 shield good penetration is generally obtained.

Active mixtures. It is often possible to take advantage of the qualities of individual gases, by using a mixture for the gas shield e.g. argon-oxygen, argon-oxygen-CO2, argon-CO2.

Even if the inert gases in their pure state are able to perform their shielding effect at any temperature, the addition of active gases improves arc stability and the transfer of the wire electrode metal to the weld pool. This occurs without impairing the shielding effect.

D. WELDING WIRES

The wires can be identified by their chemical composition and also their section morphology, which may either consist of a single metal (solid wires) or have an internal core containing granules (tubular wire).

The wires can be identified by their chemical composition and also their section morphology, which may either consist of a single metal (solid wires) or have an internal core containing granules (tubular wire).

Particular attention should be paid to the presence of grease or moisture on the surface of the wire electrode, because they could cause cracks, porosity or blowholes; in addition, if the wire electrode reel is not wound uniformly this could cause uneven wire feed resulting in unstable welding.

Solid wires usually have the same composition as the base material, with added elements able to help clean the base material. The most widely used diameters are 0.6 – 0.8 – 0.9 – 1 – 1.2 – 1.6 mm.

Tubular wires, with gas shield, do not consist of solid metal but have an internal core filled with granular powder (flux); this has the same functions as the coating on coated electrodes.

The granular powder or flux can be of rutile, basic or special type.

Compared to solid wires, tubular wires have better arc stability and deeper penetration, ensure a better-looking seam, often eliminating the need for further finishing (e.g. spray grinding) and reducing the risk of defect formation, such as porosity; of course the use of tubular electrodes requires slag removal, as for welding with M.M.A. electrodes.

The most widely used diameters are 0.6 – 0.8 – 0.9 – 1.2 – 1.6 mm.

E. THE WELDING METAL: TRANSFER METHODS

With M.I.G.-M.A.G welding procedures, the method of transferring the welding metal from the wire electrode (either solid or tubular) to the weld pool depends, as well as on the electrical welding parameters, on the wire diameter, the type of power source and the gas used. Depending on these parameters, drop transfer may be by:

1. Immersion (short-arc, dip-transfer or short circuit)

2. Spray-arc

3. Impulse or pulsed-arc

1. immersion transfer (short-arc, dip-transfer or short circuit)

The welding metal is transferred to the weld pool in the form of drops which are immersed in the pool itself, creating continuous short circuits.

This “short arc” transfer is characterised by the presence of current intensities of up to 200 A, by the use of thin solid wires, from 0.6 m to 1.2 mm, enabling thin welds and welding in all positions possible. This is obtained using direct current power sources.

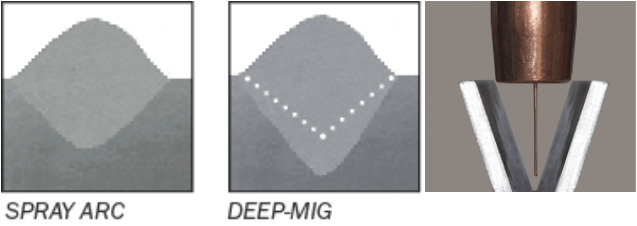

2. spray-arc transfer

This method is designed so that the drops of material are not transferred to the weld pool by contact but rather, due to the effect of the high current, are sprayed into the bath creating a continuous flow of material.

This feature is obtained using direct current power sources when the current used is high (greater than 200 A) and the wires have a diameter of more than 1 mm. A very fluid weld pool is generated, with sizeable penetration, which is suitable for horizontal welding of mainly medium and large thicknesses.

3. pulsed-arc transfer

This procedure can only be obtained with pulsed current power sources. The pulsations actually cause small-sized drops to detach themselves and therefore the typical spray arc is obtained, even with low currents. Heat generation/contribution, pool size and penetration are similar to those achieved with the spray arc method. This procedure is most often used for materials such as aluminium or stainless steel, for which the short arc welding procedure cannot guarantee sufficiently high quality results.

F. MATERIALS WELDED BY M.I.G./M.A.G.

1. Mild, carbon steels

Carbon steels are welded with direct current and electrode positive polarity (the wire electrode is connected to the positive pole) using exclusively the M.A.G. welding procedure. Applications may range from the use of CO2 only, to argon – CO2 mixtures in differing proportions (the most common is 80% argon, 20% CO2 ).

The greater the percentage of argon in the mixture the better the properties and arc stability.

The weld has very good properties, especially with short arc where dense/thick weld pools are obtained, allowing welding in all positions.

The use of wires with silicon and manganese content will lead to the elimination of impurities present in the base material and obtain good quality welds.

Bevelled seams should be prepared with thicknesses greater than 3 mm.

2. Stainless steels

Stainless steels are welded with direct current and electrode positive polarity (the wire electrode is connected to the positive pole) using exclusively the M.A.G. welding procedure.

The gas shield used should consist of Ar + CO2 or Ar + Oxygen mixtures. The proportion of argon in the mixture should never fall below 98% so as to avoid strong oxidation of the chrome present in the base material.

Seams thicker than 2.5 mm should be bevelled. Care should be taken to choose the most suitable welding material for the quality of the stainless steel being welded.

To achieve a good weld, we advise grinding the spots.

3. Aluminium and its alloys

Aluminium and its alloys are welded in direct current or pulsed current with electrode positive polarity (the wire electrode is connected to the positive pole) using the M.A.G. welding procedure.

The gas shield used is usually pure argon. Pure helium or an argon + helium mixture can also be used.

For horizontal welding, irrespective of the thickness, the spray-arc and/or pulsed-arc technique is used; the short-arc technique is used, instead, on thin vertical or corner welds. Given the properties of aluminium, milling the spots instead of grinding is advisable.

4. Other materials

The M.I.G.-M.A.G. welding procedure is also used on materials such as nickel and its alloys, copper and its alloys; for all these materials direct current with electrode positive polarity is used.

For welding copper more than 5 mm thick we advise adoption of the M.I.G. procedure but in any case the current intensity should be adjusted according to the welding position and the seam thickness.