Metal Marking & Etching Systems

Electrolytic etchers are perfect for permanent marking of various conductive metals. Our etching systems use a unique electromarking technique, without corrosive acids

As well as high quality logos, metal etching is also capable of marking simple text messages, part numbers, dates, serial numbers and other required information, directly onto the product – whether the surface is round or flat. The marking process takes a matter of seconds!

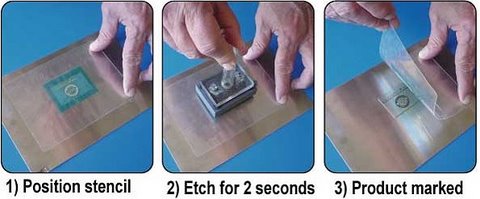

The Etching Technique

Metal etching works by passing a controlled low-voltage electric current through a pre-printed stencil. The current is transferred through the gaps in the stencil using a harmless electrolyte fluid and etches away a thin layer of the surface material leaving a dark contrasting finish on the metal.

The mark is usually generated within 2-3 seconds – depending on the material and the size or composition of the mark.

Various Stencil options available

Various types of metal marking stencils are available to suit any type of information you wish to etch onto your parts.

- Plain text or numbers

- High-resolution logos

- Serial numbering

- Part numbers

- Patterns or grid marking

more on metal etching stencils

Different etching models available

Different models are available depending on individual metal marking requirements. Etchers are made in Germany to the highest standards of quality by the world leaders in metal marking

Manual etching systems use a control unit and a hand-held marking head.

Manual metal marking

Semi-automatic systems pneumatically print the part, with the electrolytic solution automatically dosed.

Semi-Automatic metal etching

A very wide variety of conductive materials can be etched, including both ferrous and non-ferrous metals ranging from stainless steel to mild steel, aluminium (non-anodised), carbides and chrome plating.

We can recommend various electrolyte solutions specifically to mark your metal (although some are very good “general purpose” electrolytes). Most electrolytes are non-corrosive and dont require the hassle of after etching treatment.

Making metal etching easier with our accessories

Your metal etching application can be made easier with the right selection of etching accessories – such as marking heads, numbering heads, bench markers, roller-markers, print “erasing” blocks, product jiggings, stencil printers and many more…..

With the right combination of etcher, etching stencils, electrolytes and accessories, your permanent metal marking will seem more like play than work!

Etched Samples